Follow us on Social

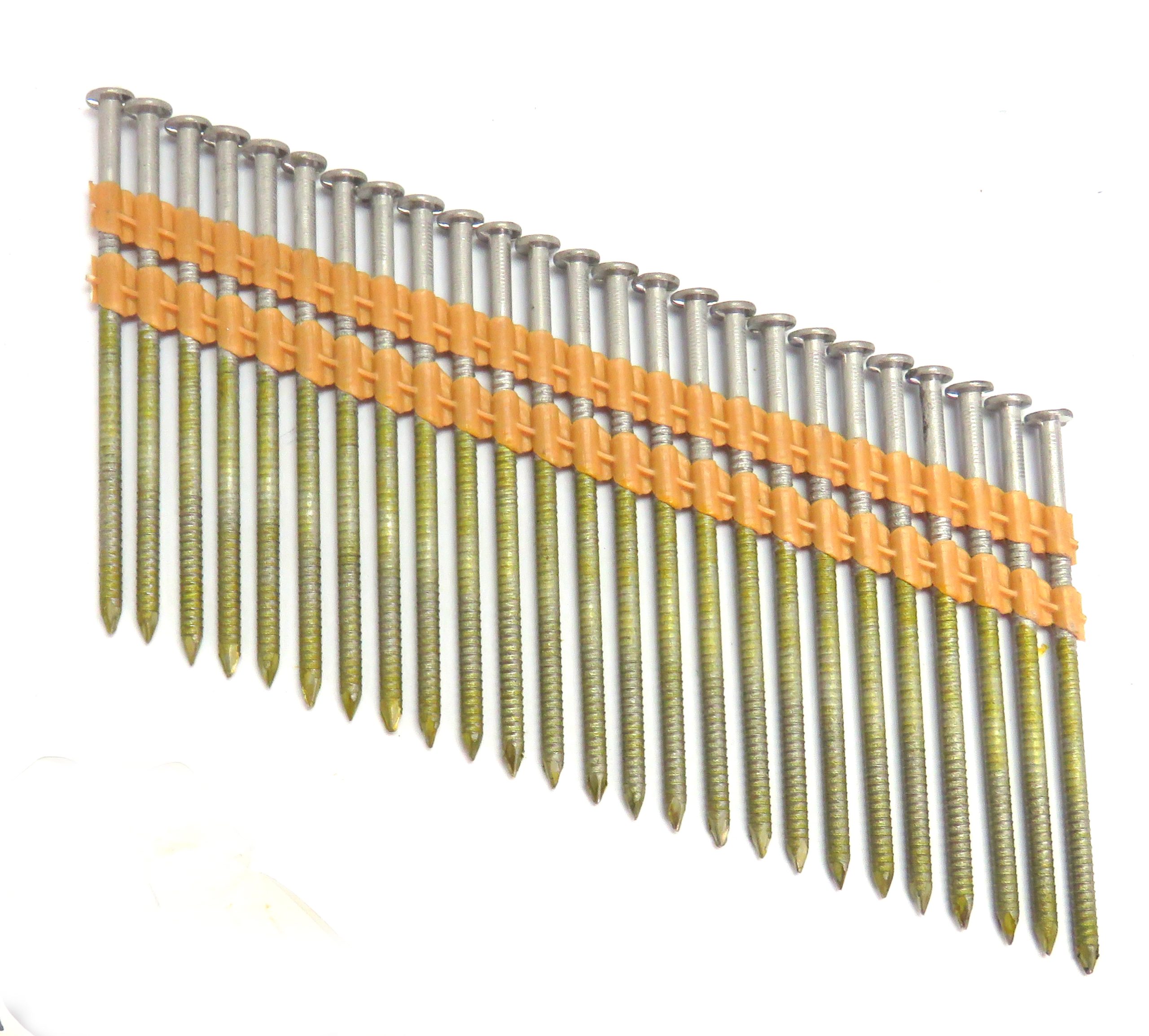

Collated Nails

Halsteel® – the Best Gun Nails

in the World!

Through many years of innovation, the Halsteel® production process has made the best, most consistent, high-quality gun nails in the world. Halsteel’s gun nails are available in many finishes, all made to the highest standards.

ZincGard®

Some companies cut corners when it comes to corrosion protection by manufacturing nails from hot-dipped galvanized wire, painting damaged heads and points with zinc paint, or even using a different coating altogether.

Tree Island Steel ZincGard® nails meet or exceed all ASTM A153 standards and are compliant to building code requirements in the US and Canada, ensuring you get the quality and product life you expect from a genuine hot-dipped galvanized nail.

In fact, we even go above when it comes to corrosion protection. Tree Island Steel ZincGard® nails have one of the thickest and most uniform hot-dipped coatings in the market. Tests show that this can provide upwards of 20 more years of service life than a standard galvanized coating.

To learn more about our ZincGard® hot-dip process, click here.

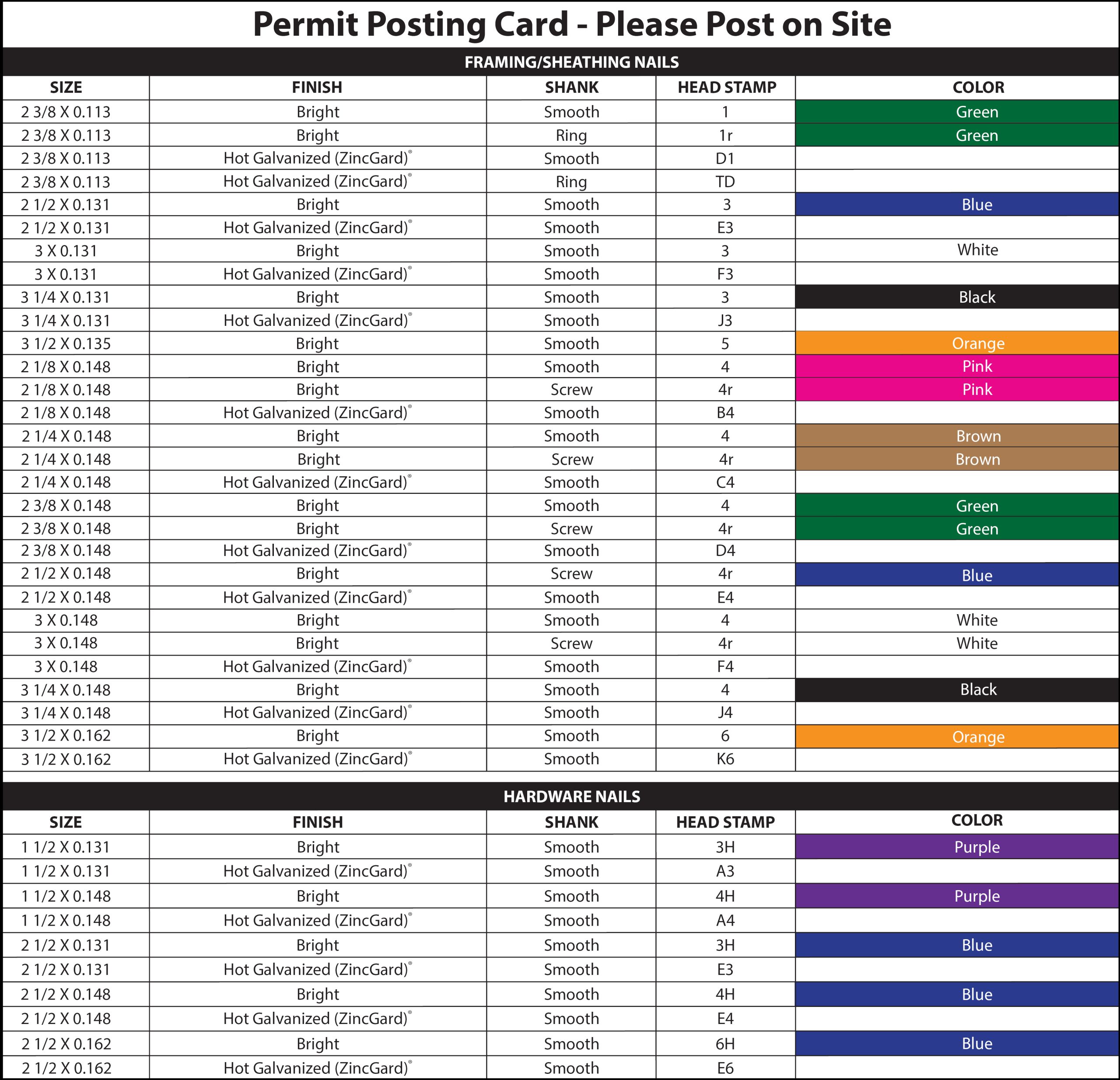

TrueSpec®

Minimize confusion and risk by using and specifying TrueSpec® fasteners. The TrueSpec® nail identification system improves job site communication and insures that correct fastener is used, reducing confusion and risk. The embossed number clearly identifies the nail diameter and the color quickly indicates the nail length. The marked nail heads are easy to identify, minimizing nailing errors.

Your Assurance of Quality, Value and Service